The Future of Business: Exploring 3D FDM Printing Technology

In today's rapidly evolving technological landscape, businesses are constantly seeking innovative solutions to enhance productivity and creativity. One such groundbreaking technology is 3D FDM (Fused Deposition Modeling) printing, which has emerged as a transformative force in various industries including art supplies, product design, and manufacturing. In this article, we will delve deep into the world of 3D FDM, exploring its applications, benefits, and the future it holds for businesses worldwide.

Understanding 3D FDM Printing Technology

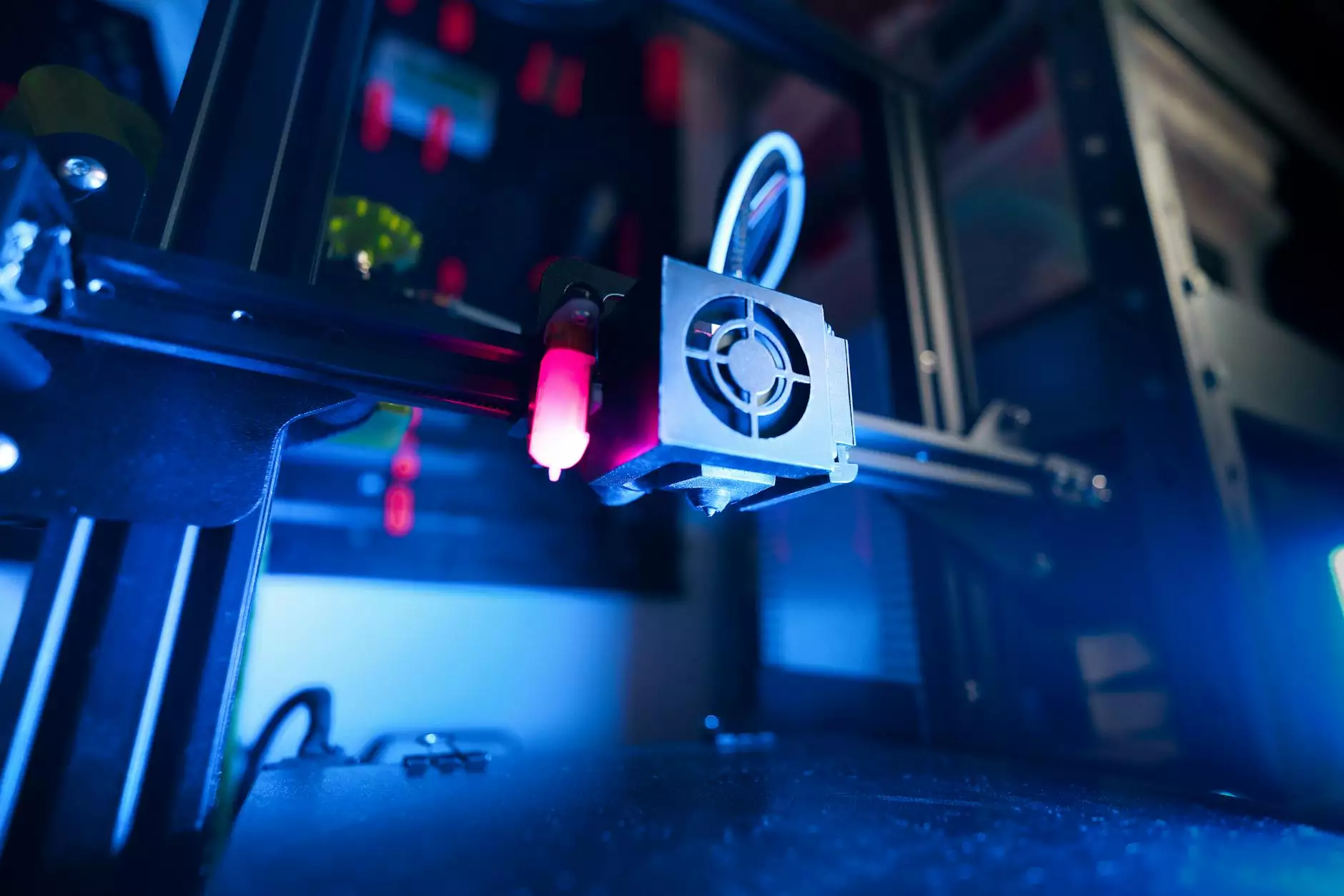

3D FDM printing is a process that creates three-dimensional objects by layering materials, typically plastic, in a precise manner. The technology began its journey in the 1980s but has gained significant traction in recent years due to advances in both the technology and the materials used. The principle is straightforward: a 3D FDM printer heats up thermoplastic filaments and extrudes them through a nozzle to build objects layer by layer.

How Does 3D FDM Work?

The 3D FDM printing process can be broken down into several key stages:

- Model Design: The first step involves creating a digital model of the object to be printed. This can be done using 3D modeling software like Blender or Tinkercad.

- Slicing: Once the model is complete, it is sent to slicing software, which converts the model into specific instructions that the printer can understand.

- Printing: The printer deposits layers of melted thermoplastic material in precise patterns to build the object layer by layer.

- Post-Processing: After printing, finishing touches may be applied, such as sanding, painting, or assembling components.

The Diverse Applications of 3D FDM in Business

The versatility of 3D FDM printing makes it suitable for a variety of applications in different sectors, including:

1. Art Supplies

In the realm of art supplies, 3D FDM printing has opened up new avenues for creativity. Artists and designers can produce customized tools, molds, and even sculptures directly from their digital designs. The ability to create unique, intricate designs with relative ease allows artists to experiment and push the boundaries of their creativity.

2. Product Design

In product design, 3D FDM technology is revolutionizing the prototyping process. Traditionally, creating prototypes could take weeks or months. However, with 3D FDM, designers can quickly produce functional prototypes to test form, fit, and function before committing to full-scale production. This rapid prototyping significantly reduces time-to-market and allows for iterative design processes.

3. Manufacturing

The manufacturing sector is witnessing a significant shift thanks to 3D FDM printing. Businesses are leveraging this technology to produce small-scale production runs, custom parts, and even end-use products. The ability to manufacture on-demand reduces inventory costs and waste, aligning with modern sustainable practices.

4. Education

Educational institutions are incorporating 3D FDM printing into their curricula, allowing students to learn about design, engineering, and prototyping. By engaging with this technology, students gain hands-on experience that prepares them for the demands of the modern workforce.

Benefits of Incorporating 3D FDM into Business Models

The integration of 3D FDM printing into business practices offers numerous advantages:

- Cost-Effectiveness: Reduces costs associated with traditional manufacturing methods, including tooling and material waste.

- Customization: Facilitates the production of customized products tailored to specific market needs.

- Speed: Accelerates the design-to-production timeline, allowing for faster market entry.

- Innovation: Encourages creativity and innovation by making it easier to experiment with designs.

- Sustainability: Minimizes waste through additive manufacturing, which uses only the necessary material to build parts.

Challenges and Considerations in 3D FDM Printing

While the benefits of 3D FDM printing are compelling, there are also challenges to consider:

1. Material Limitations

The range of materials available for 3D FDM printing, while expanding, is still limited compared to traditional manufacturing techniques. This can limit the applications for certain products that require specific material properties.

2. Resolution and Finish

Another challenge is achieving desired surface finish and resolution. While 3D FDM has improved significantly, intricate details may not always meet expectations without extensive post-processing.

3. Printer Reliability

Not all 3D FDM printers are created equal. Unreliable machines can lead to production delays and increased costs, so it’s paramount to invest in quality equipment.

Future Trends in 3D FDM Technology

The future of 3D FDM printing looks bright as the technology continues to evolve. Some anticipated trends include:

1. Material Innovation

New materials with enhanced properties are being developed, such as biodegradable filaments, composite materials, and even bio-printing materials. These innovations will expand the potential applications of 3D FDM printing in various fields.

2. Integration with Other Technologies

As businesses seek more integrated solutions, we may see 3D FDM printers that can seamlessly work with augmented reality (AR) and virtual reality (VR) technologies for design visualization and prototyping.

3. Increased Automation

With advancements in automation, 3D FDM printing processes may become more streamlined, allowing for continuous operation and the ability to produce larger batches efficiently.

4. Environmental Sustainability

As sustainability becomes crucial in business operations, the 3D FDM printing industry is expected to focus more on eco-friendly practices and materials, including the use of recycled plastics.

Conclusion

In conclusion, 3D FDM printing technology stands as a cornerstone of innovation within the business world. Its applications in art supplies, product design, and manufacturing offer businesses unprecedented opportunities to enhance creativity, reduce costs, and improve sustainability. As the technology continues to evolve and overcome existing challenges, its adoption will become ever more critical for businesses aiming to thrive in today's competitive market.

By embracing the potential of 3D FDM printing, organizations can position themselves at the forefront of innovation, ensuring they remain relevant and competitive in the years to come.