Maximize Your Productivity with a Shrink Tube Printer

In today's fast-paced business environment, efficiency and quality are key drivers of success. Among the technologies that can significantly enhance operational productivity is the shrink tube printer. This article delves into the features, advantages, applications, and considerations for choosing the right shrink tube printer for your needs.

Understanding Shrink Tube Printing Technology

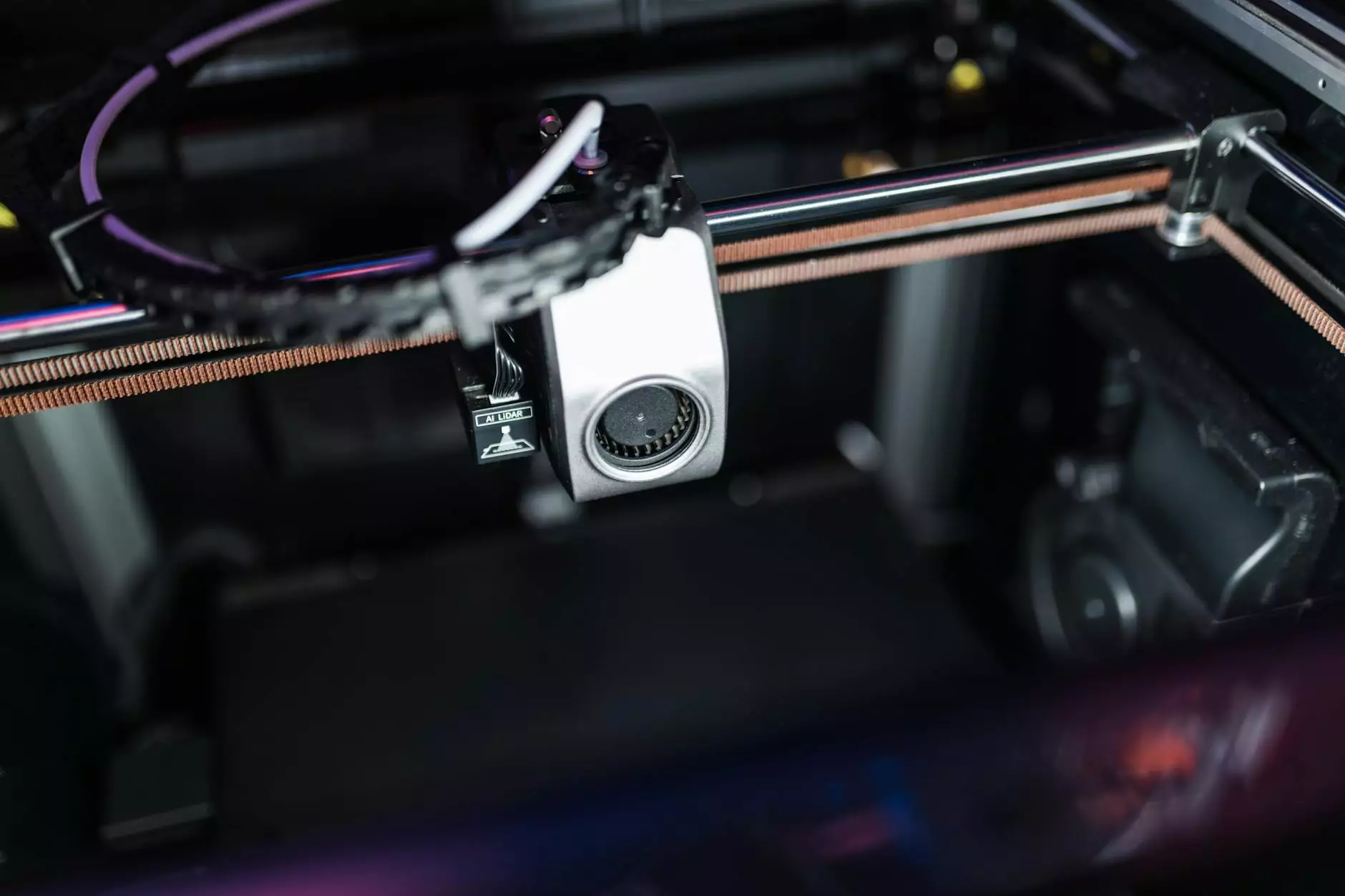

Shrink tube printers are specialized devices designed to print high-quality, durable labels on shrink tubing materials. These printers use heat to shrink the tubing around components, providing a secure fit and a professional appearance. The versatility of shrink tube printing makes it indispensable in various industries, from electronics to manufacturing.

How Shrink Tube Printers Work

The operation of a shrink tube printer involves several key steps:

- Designing the Label: Users can create custom label designs using software that interfaces with the printer. This includes choosing fonts, colors, and graphics that match the branding or specific project needs.

- Printing the Label: Once the design is finalized, the printer applies ink to the shrink tube, producing vivid and durable images or text.

- Heating the Tube: After printing, the tube is heated, causing it to shrink around the desired object, such as wires or cables, creating a snug and protective fit.

The Advantages of Using a Shrink Tube Printer

Investing in a shrink tube printer offers numerous benefits for businesses looking to optimize their labeling processes:

1. Enhanced Durability

Labels produced by shrink tube printers are resistant to moisture, chemicals, and various environmental factors. This durability ensures that labels remain legible and intact over time, reducing the need for re-labeling.

2. Customization

With a shrink tube printer, businesses can print customized labels that meet specific requirements. From different sizes to unique designs, the flexibility offered by these printers enhances branding and product identification.

3. Cost Efficiency

While the initial investment in a shrink tube printer may seem substantial, the long-term savings can be significant. By printing in-house, companies can drastically reduce costs associated with outsourcing labeling tasks.

4. Increased Productivity

Shrink tube printers allow for quick label generation, enabling businesses to keep up with production demands. The efficient process reduces downtime and maximizes throughput.

Applications of Shrink Tube Printers

Shrink tube printers are widely used in various industries, each leveraging the technology to meet specific needs:

1. Electronics

In the electronics sector, shrink tubing is crucial for labeling wires and cables. The ability to print barcodes, serial numbers, and other identifying information directly onto shrink tubing improves organization and tracking in assembly processes.

2. Automotive

Automotive manufacturers utilize shrink tube printers to label components, helping in the identification of parts and installation procedures. This practice enhances safety and efficiency in automotive assembly lines.

3. Telecommunications

In the telecommunications field, accurate labeling of cables and connectors is essential. Shrink tube printing provides a reliable method for marking communication lines, ensuring easy identification and maintenance.

4. Medical Devices

The medical industry also benefits from shrink tube printers, where clear and durable labels are necessary for compliance and safety reasons. Printing on shrink tubing helps in proper identification of medical equipment and instruments.

Choosing the Right Shrink Tube Printer

When selecting a shrink tube printer, several factors should be taken into consideration to ensure you choose the right model for your business:

1. Printer Volume

Evaluate your production needs. High-volume operations may require more robust printers capable of handling larger print jobs without compromising on quality.

2. Compatibility

Ensure that the printer is compatible with the types of shrink tubing you plan to use. Inspect the specifications to confirm that it can accommodate the widths and materials you need.

3. Ease of Use

A user-friendly interface simplifies the labeling process. Look for printers with intuitive software that allows for quick design and printing without extensive training.

4. Print Quality

The quality of the print output is vital. High-resolution printing will ensure that text and graphics are sharp, clear, and professional-looking.

5. Support and Service

Investigate the manufacturer’s support services. Reliable customer support is essential for troubleshooting and maintenance purposes, ensuring minimal disruption to your production line.

Tips for Maintaining Your Shrink Tube Printer

To ensure the longevity and efficiency of your shrink tube printer, regular maintenance is critical. Here are some practical tips:

- Regular Cleaning: Dust and debris can affect print quality. Regularly clean the print head and other components according to the manufacturer's guidelines.

- Update Software: Keep the printer’s software updated to access improvements and new features, enhancing performance and functionality.

- Inspect Consumables: Check ribbons and tubes frequently to prevent issues in print quality and ensure continuity in your labeling operations.

- Professional Servicing: Consider scheduling periodic professional maintenance to address any potential issues proactively.

Future Trends in Shrink Tube Printing

The landscape of shrink tube printing continues to evolve with advancements in technology. Here are some emerging trends to watch:

1. Integration with Smart Technologies

As businesses adopt smarter manufacturing technologies, shrink tube printers are beginning to integrate with IoT devices, allowing for real-time monitoring and automated workflows.

2. Eco-Friendly Materials

The demand for sustainable products is on the rise. Future shrink tube printers may incorporate printing technologies that reduce waste and utilize eco-friendly materials for labels.

3. Enhanced Customization Options

Advancements in design software tools will provide users with even more customization options, allowing for intricate designs and variations to suit specific branding needs.

4. Increased Automation

Automation will likely play a significant role in the future of shrink tube printing. Automated systems can streamline the label production process, further improving efficiency and reducing labor costs.

Conclusion: The Impact of Shrink Tube Printers in Business

A shrink tube printer represents an invaluable asset for businesses looking to enhance their labeling processes. By investing in this technology, companies can achieve better product identification, increased efficiency, and cost savings. The adaptability of shrink tube printers across various industries only strengthens their relevance in today’s market.

At Durafast Label, we offer a variety of high-quality shrink tube printers designed to meet the needs of any business. Explore our range of products to find the perfect solution that aligns with your operational goals and quality standards.